Zhengzhou Custom Eng. Parts Ltd.

Your Trusted Engineering Parts Manufacturing Expert

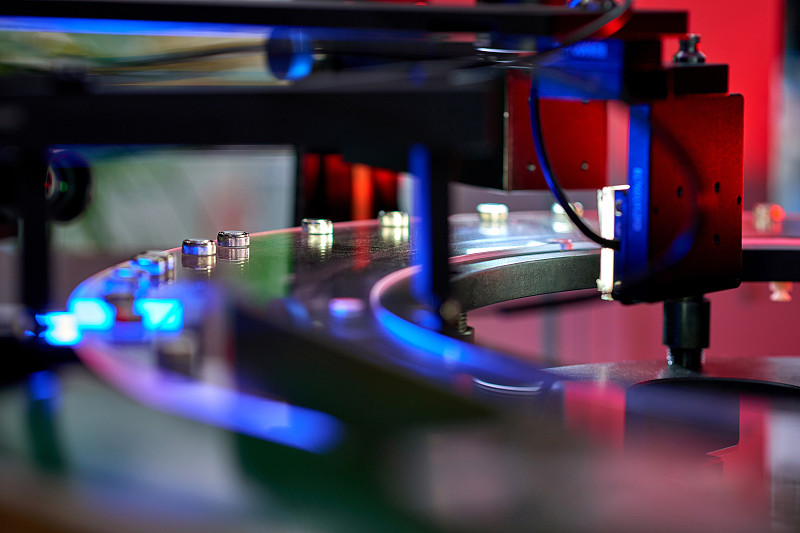

Zhengzhou Custom Eng. Parts Ltd. is a modern enterprise specializing in custom engineering parts manufacturing. With 20 years of industry experience, we are committed to providing high-quality, high-precision engineering parts machining services to global customers.

Our headquarters is located in Henan, China, with modern production facilities and advanced machining equipment. Our products are widely used in mechanical manufacturing, engineering equipment, automotive industry, aerospace, and many other fields, serving customers across 50+ countries including North America, Europe, and Southeast Asia.